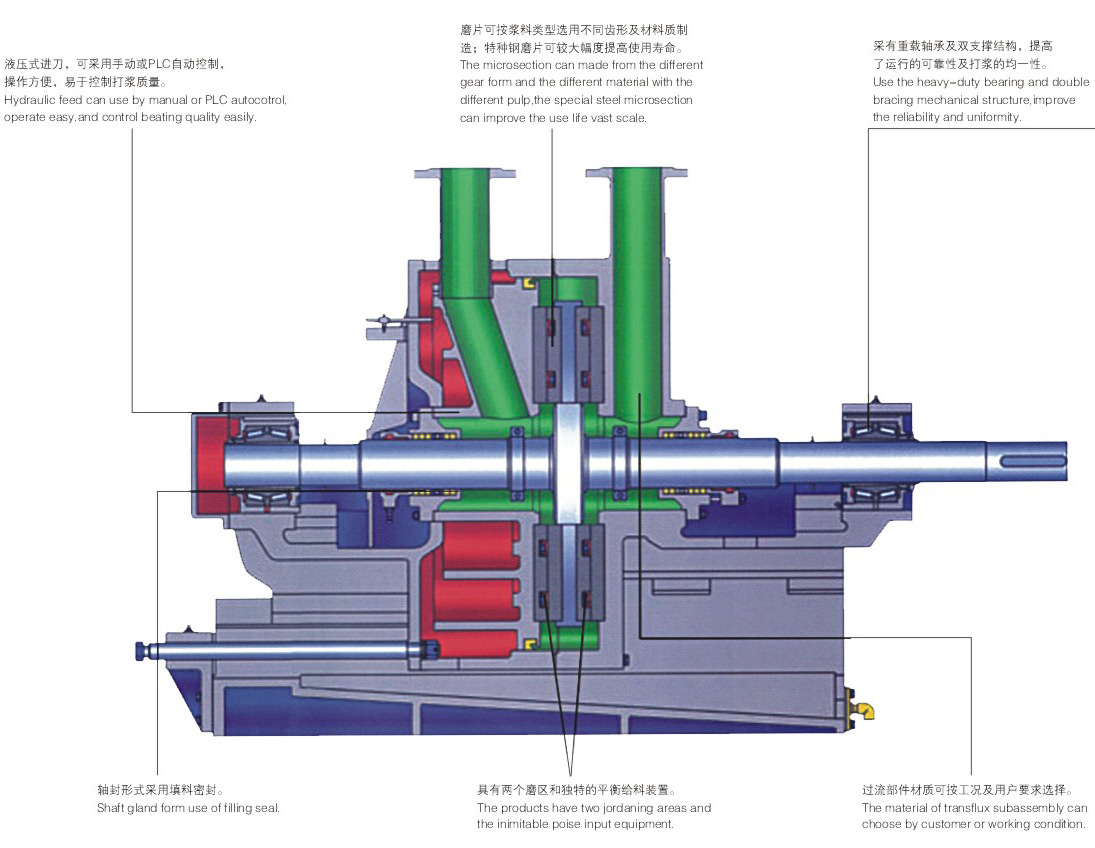

DDM series double disc refiner

DDM series double disc refiner is a new refiner specially developed by our company on the basis of digesting and absorbing foreign advanced technology and combining with the production characteristics of China's paper industry. The double-disc grinding machine has two refining zones and a unique balanced feeding device, which is twice as refining capacity as a standard single-disc refiner of the same diameter. The structure is compact, automatic control can be adopted, and the production efficiency is high. It is convenient for operation and maintenance, and is suitable for slurrying and beating of various slurries. According to the process requirements, it can be used in a single unit or in multiple series or in parallel. It is an ideal beating equipment.

The DDM double disc refiner has the following advantages:

1. There are two slurry inlets and one slurry outlet. The slurry is fed to the two refining zones by the two pipes through the two pipes, and the slurry is discharged from the slurry pipe after the refining meets the requirements.

2. The refining mechanism contains a floating rotor shaft assembly, a moving seat and two bodies. The rotor shaft assembly rotates between the two bodies, and the moving seat is controlled by two cylinders for axial movement, and the grinding plate is mounted on the rotating disc, the moving seat and a body.

3. The pressure micro-motion is used to adjust the gap of the grinding disc. The control system can adjust the relief valve gap manually or automatically by adjusting the overflow valve or proportional valve according to the slurry quality and output set by the user.

4. Special grinding discs made of special alloy steel and other materials can adapt to the selection of a variety of different slurries and greatly extend the service life.

5. The shaft seal type is sealed with a soft packing and equipped with a sealed water cooling system, so that the pressure and flow rate in the sealed chambers at both ends are kept constant.

6. Both ends of the shaft are supported by double-row spherical roller bearings mounted on the inner taper sleeve, and are lubricated with high-quality lithium grease.

7. The drum-shaped gear coupling with strong bearing performance is used to transmit torque, ensuring low noise, stable transmission, and large axial displacement compensation.

8, according to user needs, PLC programming control (constant power control) can be used to achieve automatic control and monitoring of the beating process.

MESSAGE

Welcome to the official website of Meite light industry. If you have good suggestions and comments, please fill in the form below and feed back to us. Thank you.

产品留言

Recommended products

底部-联系我们

Hangzhou Xiaoshan Meite Light Industrial Machinery Co., Ltd.

Tel: +86-571-82519727 / 83510265

Fax: +86-571-82519726

E-mail:mtqj@163.com